Wuli Industrial District

Quanzhou City Fujian Province, China

Designed with the central adjustment system to adjust fabrics in different levels of density easily and conveniently, normally equipped with different gauges of cylinders which is easy to alter and can meet the varying requirements in the knitting market.

Flexibly and easily knits different fabrics through replacing some heart parts,high investment utilization

High speed technology to meet your demand on high production and fast return of investment

Easily adjust fabric density, meet different demands of knitting market

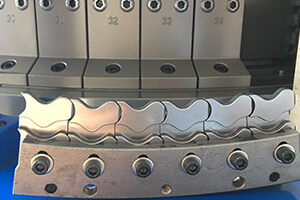

Adopting the 4 track cams seal design and equipped with knit cams, tuck cams and miss cams. High precision central raising and falling system can adjust the fabric weight conveniently and quickly.

The special design of the feeding yarn carrier makes the option of Lycra more proficient. Featuring an ergonomic design, the additional middle feeding yarn transfer ring makes it easy for personnel to monitor and carry yarn, without the machine touching the operator’s body; at the same time, the yarn carrying system is freer and steadier, satisfying the demand of machine operating and knitting at high speeds.

A machine with multipurpose functions, by replacing the heart parts, it can easily converted into 3-thread-fleece and terry machine and other machines.

By changing a few parts, the machine can be configured to produce various different cloths, such as fiber covered cotton, single pique mesh, single fleece and small stripe cloth.

Model | Cylinder Diameter | Machine Gauges | No.of Feeders | Speed |

ST-SJ3 | 23’’-68’’ | 12-50G | 3 F OR 3.2F/Inch | 20-45 RPM |

ST-SJ4 | 23’’-68’’ | 12-44G | 4 F/Inch | 20-30 RPM |

ST-SJ6 | 30’’-68’’ | 18-36G | 6 F/Inch | 20-25 RPM |

The Single Jersey Circular Knitting Machine parts perform dedicated, human hand-like knitting which adopts a 4-track cam seal design. A set of latch needles, cylinder and sinker ring all revolve along the stationary knitting cam systems.

The machine is equipped with knit cams, tuck cams and miss cams that variably controls the height of the needles and individual needle selection. High precision central raising and falling system can adjust the fabric weight conveniently and quickly.

Premium Quality Lycra can be made (For Spandex Manufacturing)

With our special design of the feeding yarn carrier, Lycra can be made as soft, elastic, flexible and more proficient than ever.

Featuring an ergonomic design, the additional middle feeding yarn transfer ring makes it easy for personnel to monitor and carry yarn, without the machine touching the operator’s body; at the same time, the yarn carrying system is freer and steadier, satisfying the demand of machine operating and knitting at high speeds.

Flexible for Knitting Varying Fabrics and Multi-functional Models

This conventional single jersey circular knitting machine can perform multi-purpose functions by just replacing the heart parts. Easy conversion into 3-thread-fleece and terry machine and other machines can be performed.

Application Area: Vest, T-shirt, Polo shirts, functional sportswear and underwear or seamless clothes(small size).

We know you have it in you: the passion for knitting lovely fabrics and an invariant taste for fashion clothing. Do you want to take it on to the next level by making your own line of single weft knit fabrics (in fast production rates while maintaining quality)?

You are in for a treat with our Single Jersey Circular Knitting Machine for fabricating single fabric in an intricate knitting manner, specifically manufactured for innovative textile and apparel industries. What’s more is you get to enjoy our China-quoted, affordable price for this special fabric equipment.

Experience hassle-free operation with its central stitch adjustment system. You can easily and conveniently adjust the fabric in different levels of fabric density. We have equipped our Single Jersey Knitting Machine with different gauges of cylinders that requires less power for excellence in fabric-making efficiency.

Application Area: Vest, T-shirts, Polo shirts, functional sportswear and underwear or seamless clothes(small size).

Applicable Yarn Materials: cotton, synthetic fiber, silk, artificial wool, mesh or elastic cloth.

The Single Jersey Circular Knitting Machine parts perform dedicated, human hand-like knitting which adopts a 4-track cam seal design. A set of latch needles, cylinder and sinker ring all revolve along the stationary knitting cam systems.

The machine is equipped with knit cams, tuck cams and miss cams that variably controls the height of the needles and individual needle selection. High precision central raising and falling system can adjust the fabric weight conveniently and quickly.

Premium Quality Lycra can be made (For Spandex Manufacturing)

With our special design of the feeding yarn carrier, Lycra can be made as soft, elastic, flexible and more proficient than ever.

Featuring an ergonomic design, the additional middle feeding yarn transfer ring makes it easy for personnel to monitor and carry yarn, without the machine touching the operator’s body; at the same time, the yarn carrying system is freer and steadier, satisfying the demand of machine operating and knitting at high speeds.

Flexible for Knitting Varying Fabrics and Multi-functional Models

This conventional single jersey circular knitting machine can perform multi-purpose functions by just replacing the heart parts. Easy conversion into 3-thread-fleece and terry machine and other machines can be performed.

| EQUIPMENT | STANDARD | OPTION A | OPTION B |

|---|---|---|---|

| Needle | Groz Beckert, Germany | Samsung, Korea | Yantex, Korea |

| Sinker (For single knit) | Kern Libbers, Germany | Samsung, Korea | Yantex, Korea |

| High Rigidity Special Design Robust Frame | SINTELLI | / | / |

| Zirconia Yarn Guide | SINTELLI | / | / |

| Yarn Feeder | SUN Feeder (B19) | SUN Feeder (B23K) | Global OR Memminger |

| Automatic oil Lubricator | Shengsong, Taiwan | Taiguan, Taiwan | Can be customized |

| Tube Creel | Triangle Creel | Creel with tube | / |

| 4 PCS Teeth Belt | MEGADYNE | / | / |

| Micro-computer control panel (3-shift counter and 4 digital RPM counter) | SINTELLI | Can be customized | / |

| Air System | Taiguan, Taiwan | Shengsong, Taiwan | Taishan |

| Inverter | TOSHIBA, Japan | Delta, Taiwan | Yolico, Japan |

| Motor | Teco, Taiwan | Sintelli | Delta, Taiwan |

| Take Down System | Fabric open take-down system | Sintelli Folding & Rolling take-down system | / |

| Cylinder | SINTELLI Japanese High Precision Alloy Steel material | / | / |

| Machine CAM setting | Single Jersey: 4 tracks Double Jersey: Dial 2 tracks, cylinder 4 tracks | Exchange cam parts for structions | / |

| Lycra feeder | SUN WAL5-4A/B | SUN WAL2-4A/B | Memminger |

High Transfer Capability

Flexible and easily knits different fabrics. Heart/Core parts can be easily switched and replaced, ensuring complete utilization in many years before wear.

High-Speed Technology

Everything is highly digitized. Also, quality and quantity are both met with this high speed technology meeting your demand with capabilities of high production rates in hand with its quality knitting. Quicker return of investment is met in a shorter lead time.

Central Stitch Adjustment System

Easily adjust fabric density (GSM), meeting different demands of knitting market.

Power Saving Lube Oil System

Adapts an oil bath to lubricate the wire race bearing thus running the machine smoothly while saving power and energy.

The Single Jersey Circular Knitting Machine parts perform dedicated, human hand-like knitting which adopts a 4-track cam seal design. A set of latch needles, cylinder and sinker ring all revolve along the stationary knitting cam systems.

The machine is equipped with knit cams, tuck cams and miss cams that variably controls the height of the needles and individual needle selection. High precision central raising and falling system can adjust the fabric weight conveniently and quickly.

Premium Quality Lycra can be made (For Spandex Manufacturing)

With our special design of the feeding yarn carrier, Lycra can be made as soft, elastic, flexible and more proficient than ever.

Featuring an ergonomic design, the additional middle feeding yarn transfer ring makes it easy for personnel to monitor and carry yarn, without the machine touching the operator’s body; at the same time, the yarn carrying system is freer and steadier, satisfying the demand of machine operating and knitting at high speeds.

Flexible for Knitting Varying Fabrics and Multi-functional Models

This conventional single jersey circular knitting machine can perform multi-purpose functions by just replacing the heart parts. Easy conversion into 3-thread-fleece and terry machine and other machines can be performed.